(Jasud supplies plastic sheets that are used to make the following items. The images give a clarification which sheet to order for your Orthotics & Prosthetics products.)

Applications

- They are mainly used for making various types of Foot Orthoses, Prosthetic Sockets, Upper and Lower Limb Orthoses and Corsets

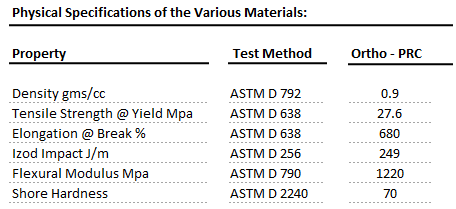

Characteristics

- This range of sheets are extruded from prime specially blended grades of Polypropylene.

- They are lightweight, stiff, stable and have a high impact strength.

- They have a very good melt strength which results in even sagging upon heating resulting in a uniform thickness on the end product. Hence they are excellent for suction moulding applications. Due to this property there is no need to keep a stockinette underneath the sheet when kept for heating in an oven. A Teflon sheet is recommended so that impression of the oven tray does not get transferred onto the sheet when it melts.

- They are recommended for fabricating Weight bearing applications since they have a unique hinge ability which enables repeated flexing without fracturing.

- There is no stress whitening caused upon impact due to its special formulation.

- They are resistant to Human Sweat, Cosmetics, Skin Creams, Detergents and Disinfecting Solutions, this results in a longer life of the orthoses/prostheses.

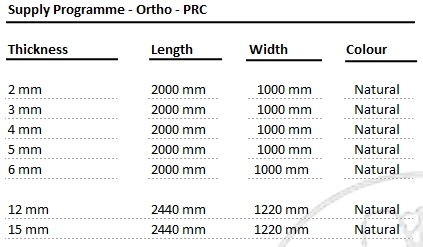

Supply Programme

- We can supply in 1000mm x 2000mm size in thicknesses ranging from 2mm to 6mm for Orthotics and in 1220mm x 2440mm size in thicknesses 12mm and 15mm for Prosthetics.

- The standard colour is natural

- Specific sizes and colour can be supplied on Custom basis

Temperature Range

- Recommended heating time in Oven is 3 to 4 minutes per mm thickness of sheet at an oven temperature between 180 to 200 degrees Celsius. This shall vary based upon the Oven construction.